|

GLM is proud to introduce our Needle & Caged Bearing!

They Look the Same but are NOT the Same!

The OEM Bearing 31-17514A2 is plastic and can fail at high-demand, high-horsepower

situations. GLM

manufactures the same bearing but with a metal cage designed to perform

in those situations.

GLM's metal caged bearing out performs the OEM plastic bearing. Our

needle rollers are mainly

supplied by needle roller specialist or OEM manufacturers. The

rollers are made of Bearing

Steel (SAG 52100) and have been subjected to heat treatment

and precision grinding. The

hardness is HV700-860 (HRC 60-66). Both ends of our rollers

used in marine engines are shaped

with a special profile, known as "crowning".

What is Crowning?

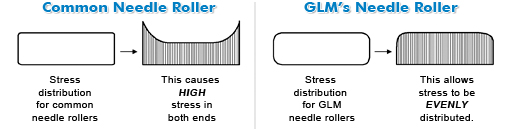

Crowning is also known as "controlled contour", or coded as "ZB2". The crowning is to shape

both ends, in a .040" - .080" area, to have a parabolic curvature (as the figure below, however

it is difficult to see this curvature with the naked eye). The purpose of crowning is to avoid high

stress consentration at the end ares of rollers and to ensure even contact stress between roll-

ers

and the race. Because the crowning lessens the roller's maximum stress, it can increase

bearing life significantly.

How About the Cages?

Because the cage is constantly subject to friction between rollers and the race, the hardness

of each

corresponding contact area must be assigned appropriately to archive optimal bear-

ing life. As a general

rule, the roller and surface of the inner and outer races should have high-

er hardness, HV 700~860 (HRC 60~66),

to ensure wear resistance. The hardness of the cage

should be slightly less than the rollers. Also,

the cage material should be tough enough to a-

void cage fracture during high-load, high-speed

operation.

To ensure the high-quality heat treatment of the cages, GLM cages use Swiss made,

auto-

matic carbonitriding furnace. The strict quality inspection also applied to every production lot

to make sure the surface hardness, case depth, and toughness are consistent with the top

quality standards.

|